CASE STUDY

LONDON BOX SASH REVIEW

Installed a Soukup Crafter & Hydraulic Frame & Sash Cramp London Box Specialise in Manufacturing Traditional Sliding Sash Window Replacement Market in the London Area, Please see Twitter entries of this installation https://twitter.com/iwmachines4wood and U Tube video of machine trenching to Cill Section for the boxes https://www.youtube.com/watch?v=tOEygG5vd4 on their machine.

CASE STUDY

PCW (PERFECT CRYSTAL WINDOWS)

Soukup Crafter installed at a Leading London UPVC Window Manufactures Starts Making Wooden Windows on Soukup Crafter in April 2014

Perfect Crystal Windows. started to manufacturing Timber Windows to meet growing demand for quality Timber Windows,

Owner of PCW Windows Quotes :-

I had a lot of conversations with a lot of companies, but nothing quite added up for PCW.

Until they met Ian Brown of IWM Ltd. “When we found the Soukup Crafter it was like a dream come true! “With Ian’s knowledge and experience, I knew we would get the right machine for us. Everything came on time, the installation was quick and it was all set-up and ready to go in no time “

CASE STUDY

CARRS WINDOWS

Please see enclose some U Tube Videos we made of the Last Soukup Crafter Installation at Carrs Windows a young 6 Year Old Joinery Company with Five Man in Skipton Carrs Windows Ltd. You are more than welcome to talk to discuss how the machine has transformed his business compared to previously using his time consuming tradition machinery manufacturing his Windows & Doors.

Carrs Windows Making the Boxes for Sliding Sash Window https://youtu.be/wkBG0_auKpk

Soukup Crafter Producing Window Beading https://youtu.be/_Q-0An2HVYs

CASE STUDY

TODI & BOYS LTD

Having extensively researched the machinery market, Todi & Boys found various options but none that could be supplied from one manufacturer – or indeed anyone who knew how to produce UK windows and doors!

Todi & Boys was delighted and impressed with IWM & Soukup Machinery’s project approach of supplying window machinery dedicated

to the UK window market complete with Soukup Wincreator software and Soukup tooling designed to effectively manufacture UK casement and sliding sash windows as well as door and joinery requirements with its knock-down component production methodology.

This unique approach revolutionised Todi & Boys’ production. The new installations meant it was able to achieve business ambitions and objectives using the following machines:

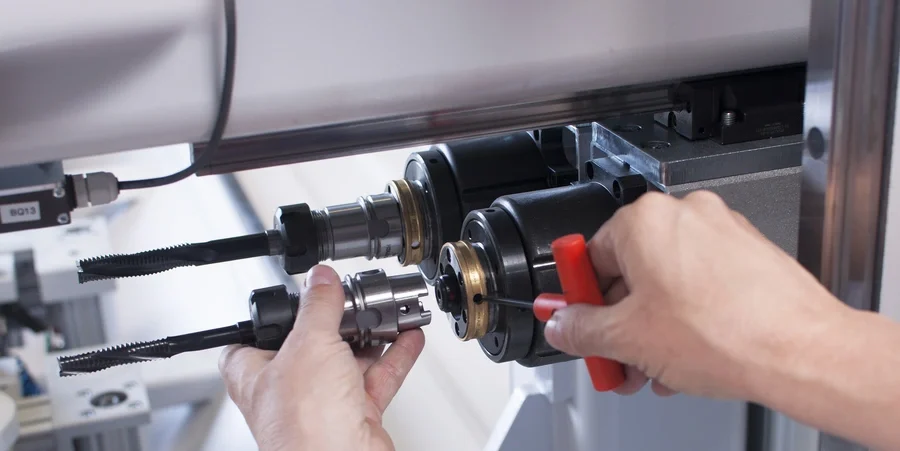

• Soukup CNC window centre, model Crafter, a Soukup CNC automatic crosscut, model Crossline 500

• Soukup CNC milling and drilling machine, model Versa DM

• Soukup five-head moulding machine, model GS 5

• Soukup hydraulic frame and sash cramp, model FP 32:21.

All the CNC machines are linked to the Soukup Wincreator software, so all production orders are sent from the office direct to each machine, such as the Soukup crosscut, model Crossline 500, coupled with a label printer which prints all customers’ order details attached to the components throughout the production process on the Soukup Crafter CNC window centre and Soukup milling and drilling, model Versa completing the process for hinges, handles, triple vents etc – all from one Soukup Wincreator software.

CASE STUDY

WOOD & WISDOM

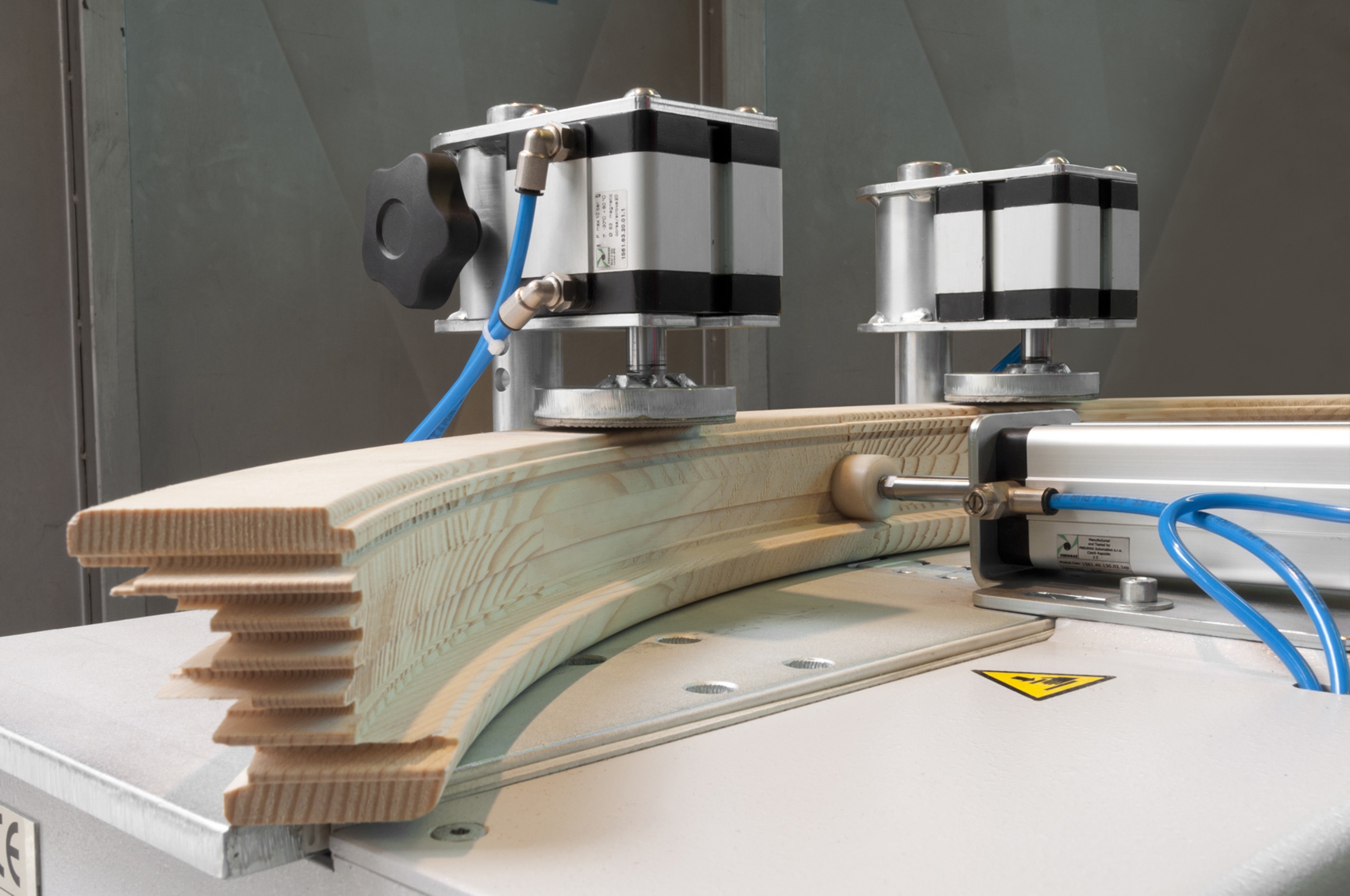

The company saw the first installation of a CRAFTER machine in the UK. Adam King, owner of the company, says: “This investment has started a complete change from conventional joinery to modern, efficient window production. It´s not a problem, as in the past, to take an order of 50 custom-made windows and make it without any pressure“. The machining center CRAFTER was the first line that used the milling unit for decorative corners on sliding sash windows. Recently, the production has been expanding with new types of mock sash windows, reminding sliding windows with their decoration.

video: CRAFTER – Soukup window machine

CASE STUDY

SANDERSON BROTHERS

They use the knock-down system for producing outward opening and sliding windows. The production of sliding windows with their sophisticated and diverse nature using the knock-down system has been particularly successful since this has never previously been achieved using a knock-down system. The WIZARD 4L machining centre using data from WinCreator for the preparation of orders and the tool system ZUANI surprised in their complexity the company owner Ian Sanderson. Employees of the company have quickly got used to the new way of production and use the machine’s capacity to be able to dedicate more time to special products that customers demand from them.

Sanderson brothers have extended their premises this year as they needed more space for a show-room and offices. This created conditions for a new workplace for the preparation of the material. In the new premises, there is an automatic cross-cut saw Crossline 500 and a new filter for central extraction. The main production hall has more space now for better organization of production and assembly of complex contracts.