CNC (Computer Numerical Control) technology has transformed the woodworking industry, allowing manufacturers to produce precision components quickly, efficiently, and consistently. Whether you’re making windows, doors, furniture, or intricate joinery, CNC machines play a vital role in modern production. At International Woodworking Machinery, a wide range of CNC woodworking machines are available to suit different workshop needs – from compact routers to advanced machining centres.

What Is a CNC Woodworking Machine?

A CNC woodworking machine automates cutting, shaping, drilling, and profiling tasks that would traditionally require multiple manual operations. Using digital programming, it follows exact coordinates to produce repeatable, high-accuracy results, ensuring minimal waste and faster turnaround times. This makes CNC technology ideal for both high-volume manufacturing and bespoke joinery production.

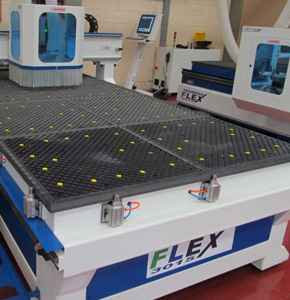

CNC Routers

CNC routers are among the most versatile woodworking machines available. These machines can cut, carve, and shape panels, solid timber, and composite materials with incredible accuracy. They are often used for cabinet production, decorative panel work, and furniture manufacturing. CNC routers can feature automatic tool changers, vacuum beds, and servo-driven motion systems for speed and precision.

Many workshops choose CNC routers for their ability to handle complex designs and produce detailed components that would be time-consuming to create manually.

CNC Machining Centres

A CNC machining centre takes automation a step further. These advanced systems are designed to carry out multiple processes such as milling, drilling, grooving, and slotting in a single operation. Machining centres are ideal for joinery workshops producing timber windows, doors, and frames. They combine speed with flexibility, allowing users to switch between different designs and dimensions with minimal downtime.

At IWM, you’ll find high-performance CNC machining centres from trusted European brands, engineered specifically for timber manufacturing environments where accuracy and reliability are critical.

CNC Window and Door Machines

For businesses specialising in timber windows and doors, CNC window and door machines offer a dedicated solution. These machines are purpose-built to handle the specific joinery processes required for sash, casement, and bespoke frame production. They can automatically perform cutting, drilling, mortising, and slotting operations, enabling craftsmen to produce perfectly fitted components every time.

The Soukup range available through IWM is a leading choice in this category, designed for both small joinery shops and large-scale manufacturers.

CNC Cross-Cutting and End-Tenoning Machines

While routers and machining centres handle shaping and profiling, CNC-controlled cross-cutting and tenoning machines ensure accurate cutting and joint preparation. These machines provide exceptional repeatability, which is essential for batch production of timber frames, doors, and furniture components. Many models include automatic feeding systems and programmable stops to further improve efficiency.

Choosing the Right CNC Machines for Your Workshop

When selecting a CNC woodworking machine, consider the type of work you do most often. A small bespoke joinery shop may benefit from a compact CNC router, while a larger manufacturer producing hundreds of windows a week would require a more advanced machining centre. Factors such as workpiece size, material type, tool change requirements, and production volume will help determine the ideal setup for your operation.

Whether you’re upgrading existing machinery or investing in your first CNC system, it’s important to work with an experienced supplier who understands both your products and your production goals. Contact us today for more information.

CNC Machines FAQs

What are the main advantages of CNC woodworking machines?

CNC woodworking machines improve precision, consistency, and efficiency while reducing waste and manual labour. They enable complex designs to be produced quickly and accurately, which increases productivity and profitability.

Which CNC machine is best for making timber windows and doors?

A dedicated CNC machining centre or window and door CNC system is best for this application. These machines are designed to handle the multiple operations involved in frame and sash manufacturing.

Do CNC machines require specialist training to operate?

Most modern CNC machines come with intuitive control systems and training support. While some initial setup knowledge is required, operators can quickly learn to program and run jobs safely and efficiently.