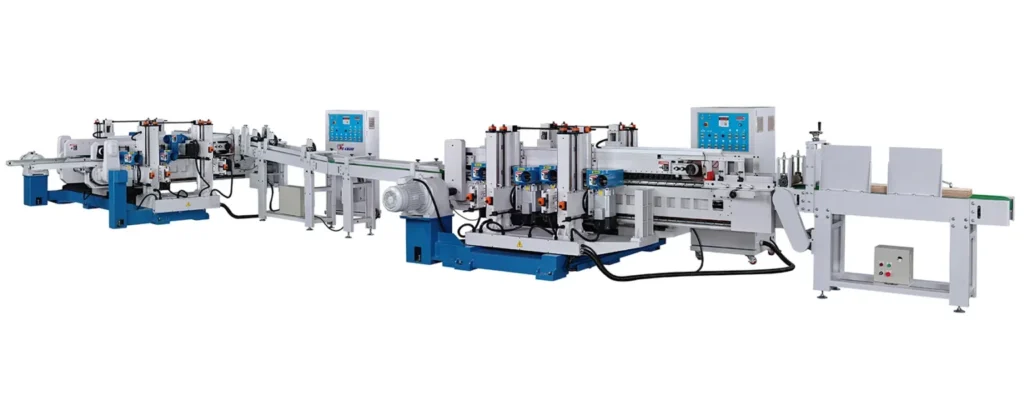

ECT-Windotec Series

Please contact us for pricing

The ECT-Windotec Single End Tenoner is a rugged, versatile workhorse tailored for woodworking professionals. With its robust chromate-hardened table, adaptable handling controls, multi-axis milling capabilities, integrated saw, and enhanced safety features, it’s well-suited for high-precision tenoning tasks across a variety of product applications.

1. Working Table

- The table surface undergoes chromate hardening, giving it exceptional durability and wear resistance.

- Offers both automatic and manual handling controls, catering to a range of workflow preferences.

- Equipped with horizontal and vertical pneumatic clamps to ensure workpieces stay firmly secured throughout operations.

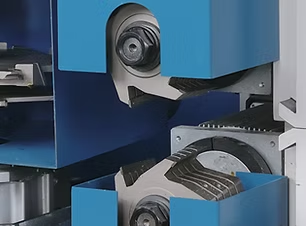

2. Milling Systems

- Horizontal Milling: Features top and bottom horizontal milling units. Configuration options vary across models in the Windotec series to meet different production needs.

- Vertical Milling: Some models include vertically oriented milling spindles, offering additional versatility—perfect for more complex tenoning or profiling tasks.

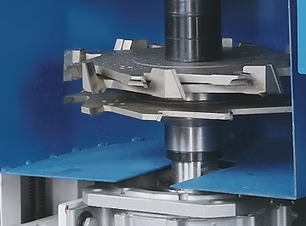

3. Main Saw Unit

Integrates a main saw within the machine for trimming or crosscutting, streamlining operations in one compact setup.

4. Safety Features

All cutting tools are protected by acrylic guards, enhancing operator safety while maintaining visibility and accessibility

The ECT-Windotec Series embodies precision woodworking excellence with a thoughtful blend of safety, stability, and flexibility.

Send Enquiry

Please answer the questions below, tick the relevant boxes, and submit the form for a detailed machine quotation.

Description

| SPECIFICATION | ECT-Windotec 3 | ECT-Windotec 5 | ECT-Windotec 6 |

| Working table | |||

| Size | 800 x 400mm | 800 x 400mm | 800 x 400mm |

| Fence length | 2400mm | 2400mm | 2400mm |

| Compressed air | 2pcs | 2pcs | 2pcs |

| Main saw unit | |||

| Motor horse power | 5hp | 5hp | 5hp |

| Spindle speed | 3000rpm(50Hz) | 3000rpm(50Hz) | 3000rpm(50Hz) |

| Spindle diameter | 30mm | 30mm | 30mm |

| Sawblade diameter | 450mm | 450mm | 450mm |

| Max. cutting height | 150mm | 150mm | 150mm |

| Top and bottom horizontal spindles | |||

| Motor horse power | – | 3hp x 2pcs | 3hp x 2pcs |

| Spindle speed | – | 3000rpm(50Hz) | 3000rpm(50Hz) |

| Spindle diameter | – | 40mm | 40mm |

| Spindle length | – | 150mm | 150mm |

| Sawblade diameter | – | 160mm | 160mm |

| Vertical spindle 1 | |||

| Motor horse power | 10hp | 10hp | 10hp |

| Spindle speed | 3000rpm(50Hz) | 3000rpm(50Hz) | 3000rpm(50Hz) |

| Spindle diameter | 40mm | 40mm | 40mm |

| Spindle length | 180mm | 180mm | 180mm |

| Cutter diameter | 350mm | 350mm | 350mm |

| Vertical spindle 2 | |||

| Motor horse power | – | – | 10hp |

| Spindle speed | – | – | 3000rpm(50Hz) |

| Spindle diameter | – | – | 40mm |

| Spindle length | – | – | 180mm |

| Cutter diameter | – | – | 350mm |

| Weight | |||

| N.W. | 1850kg | 2200kg | 2450kg |

| G.W. | 2000kg | 2350kg | 2600kg |

| Dimensions | |||

| Machine size | 2080x2700x1900mm | 2740x2700x1900mm | 3190x2700x1900mm |

| Packing size | 2290x2000x2100mm | 2850x2000x2100mm | 3300x2000x2100mm |