In modern woodworking and joinery production, accuracy and repeatability are critical. Whether you are manufacturing window frames, door components, furniture parts, or structural timber elements, clean and consistent notches are essential for strong joints and efficient assembly. This is where notching machines for wood come into their own.

While the term “notching machine” is used across several industries, not all notching machines are designed for woodworking. Understanding what a true woodworking notching machine does, and how it differs from machines used in pallet or pipe production, can help avoid costly mistakes when specifying equipment.

What Are Notching Machines for Wood?

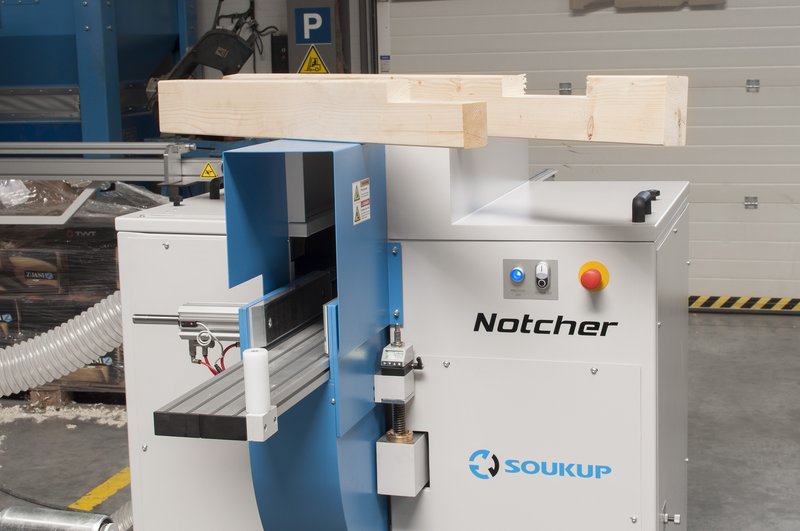

Notching machines for wood are purpose-built woodworking machines designed to remove precise sections of material from timber or engineered wood components. These notches allow parts to interlock, align, or seat correctly during assembly.

In woodworking environments, notching machines are commonly used to produce square, rectangular, or profiled cut-outs in solid timber, laminated sections, or panel-based components. The focus is on accuracy, surface quality, and repeatability, especially where parts must fit together cleanly without excessive hand finishing.

Unlike manual routing or sawing operations, a dedicated notching machine ensures consistent results across high volumes, making it ideal for production settings rather than one-off work.

Typical Applications in Woodworking

Notching machines for wood are widely used across several woodworking sectors. Common applications include:

- Window and door frame production, where accurate jointing is essential

- Furniture manufacturing, including frame and carcass construction

- Timber construction elements such as posts, rails, and beams

- Joinery workshops producing repeatable components

- Panel processing where rebates or seating notches are required

In many cases, notching machines are integrated into wider production lines alongside cross-cut saws, tenoners, or CNC machining centres to streamline workflow and reduce manual handling.

How Woodworking Notching Machines Work

A woodworking notching machine typically uses cutter heads, saw blades, or milling tools to remove material from a defined area of the workpiece. The timber is securely clamped or guided to ensure stability throughout the cut.

Key characteristics of notching machines for wood include controlled feed, rigid machine construction, and fine adjustment capabilities. This allows operators to set notch dimensions accurately and maintain consistent results across multiple pieces.

Depending on the machine design, notching can be performed from one or more sides, with some machines capable of producing complex joints or stepped profiles in a single operation.

What Notching Machines for Wood Are Not

One of the most common points of confusion is between woodworking notching machines and notching machines used in other industries. While they may share a similar name, their function and construction are very different.

Pallet Notching Machines

Pallet notching machines are designed specifically for high-speed pallet production. Their primary purpose is to notch stringers quickly so pallet forks can enter from multiple directions.

These machines prioritise speed over precision and are built to handle rough-sawn timber. Surface finish, tight tolerances, and joint accuracy are not the focus. As a result, pallet notchers are not suitable for joinery, furniture, or window manufacturing where precision is essential.

Pipe and Tube Notching Machines

Pipe and tube notching machines are used in metalworking industries to notch steel or aluminium tubes for welding and fabrication. These machines operate on completely different principles and materials.

They are not designed for timber, do not accommodate woodworking tolerances, and cannot deliver the surface finish required for wood-based joints. Despite the shared terminology, pipe notchers have no crossover with woodworking machinery.

Why Choosing the Right Type Matters

Selecting the wrong type of notching machine can lead to poor joint quality, excessive rework, and inefficient production. Woodworking notching machines are engineered with timber behaviour in mind, including grain direction, tear-out control, and dust extraction.

For businesses producing joinery or furniture components, investing in the correct machine ensures accuracy, repeatability, and long-term reliability. It also allows notching operations to be carried out safely and efficiently, reducing reliance on manual methods.

When a Dedicated Notching Machine Makes Sense

A dedicated notching machine for wood is particularly valuable when notching is a frequent or critical part of production. If notches are required on a regular basis, or must align perfectly with other machined features, manual methods or general-purpose machines can quickly become a bottleneck.

In these cases, using a specialist notching machines solution designed for woodworking helps maintain output quality while improving production efficiency.

Contact IWM today for more information about Notching Machines.

Notching Machines for Wood FAQs

What are notching machines for wood used for?

Notching machines for wood are used to create precise cut-outs in timber or wood-based components so parts can fit together accurately during assembly.

Can pallet notching machines be used for joinery work?

No. Pallet notching machines are designed for speed and rough timber processing. They do not provide the accuracy or surface finish required for joinery or furniture production.

Are woodworking notching machines suitable for CNC integration?

Yes. Many woodworking notching machines can be integrated into production lines or used alongside CNC equipment to improve workflow and consistency.