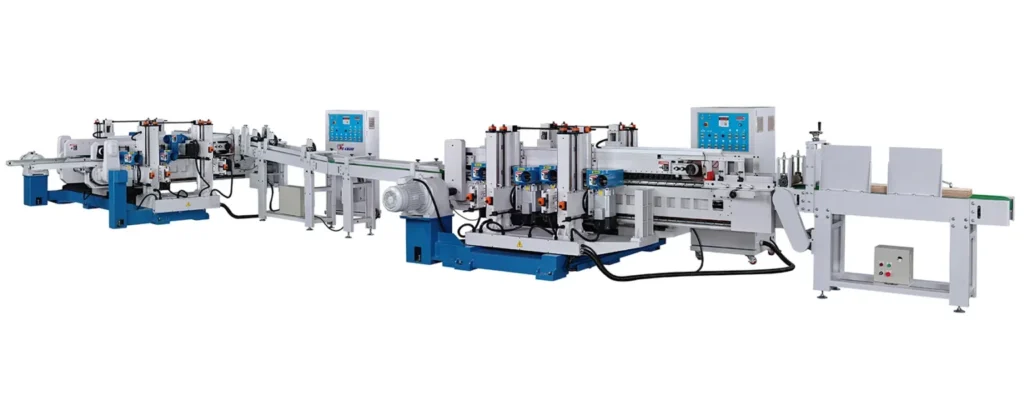

NC Type Automatic Double End Tenoner

Please contact us for pricing

The NC Type Automatic Double End Tenoner combines advanced automation, precision control, and quick setup capabilities to streamline tenoning workflows. Its comprehensive features – from NC servo adjustments and HSK tooling to automatic dogs and recipe storage—make it an ideal choice for high-efficiency, repeatable manufacturing across a variety of woodworking applications.

Key Features

- Equipped with NC positioning for top pressure hold-downs and the movable side of the machine, enabling automatic adjustment of working width and thickness.

- Features NC servo positioning for all working units across both horizontal and vertical axes, as well as the infeed reference fence.

- Utilizes HSK 63F tool interface with direct-driven high-frequency motors for rapid tooling changes in moulding systems.

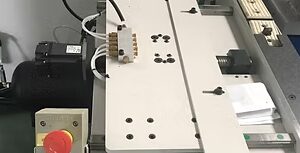

- Incorporates automatic dogs – devices that pop up as soon as an incoming workpiece is detected, completely eliminating manual dog set-ups.

- Includes a user-friendly HMI (Human-Machine Interface) supporting tooling offset entry and an optional upgrade to store/upload working parameters (recipes) for up to 100 tooling sets.

- Fully compatible with a broad range of working units, including cutting, profile moulding, chamfering, sanding, and drilling applications.

Automatic Double End Tenoner – NC Type (Fully Automatic)

The Automatic Double End Tenoner – NC Type is a fully automated woodworking solution designed to drastically reduce operator calibration time between jobs, providing both accuracy and efficiency.

Send Enquiry

Please answer the questions below, tick the relevant boxes, and submit the form for a detailed machine quotation.