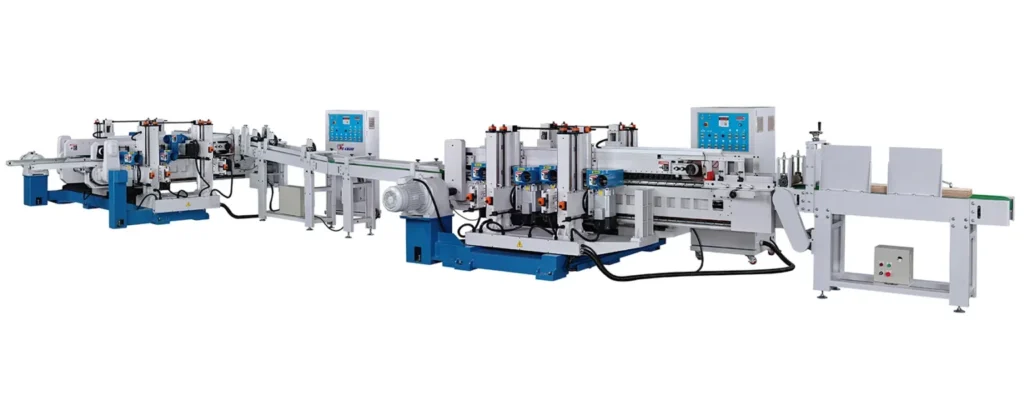

Single End Grooving Machine – ECT-C2

Please contact us for pricing

The Single End Grooving Machine ECT‑C2 is a specialized grooving solution engineered for woodworking environments, designed to deliver precision and operational flexibility. Its key features include:

Customized Infeed Fence

The infeed fence travels smoothly along precision linear guideways, guaranteeing accurate 90° alignment as workpieces are fed into the machine—enhancing consistency and reducing errors.

Top and Bottom Saw Unit Configuration

Equipped with saw units positioned both above and below the workpiece, these can be adjusted independently in horizontal and vertical directions. This enables precise control over groove placement and depth, catering to diverse cutting needs.

The Single End Grooving Machine ECT-C2 is thoughtfully designed to support precise, customizable grooving. Its combination of guided feeding and independently adjustable saw units makes it a versatile tool that fits various production scenarios—particularly those demanding accuracy and flexibility.

Send Enquiry

Please answer the questions below, tick the relevant boxes, and submit the form for a detailed machine quotation.

Description

| SPECIFICATION | |

| Working width | 60-1200mm |

| Working thickness | 6-60mm |

| Working length | 100mm and over |

| Feed Chaintrack | |

| Motor horse power | 2hp |

| Feed speed | 5-25m/min |

| Grooving System | |

| Motor horse power | 3hp x 2pcs |

| Spindle speed | 3450rpm(60Hz) |

| Spindle diameter | 25.4(30)mm |

| Sawblade diameter | 205-255mm |

| Weight | |

| N.W. | 1000kg |

| G.W. | 1090kg |

| Dimensions | |

| Machine size | 2070x960x1480mm |

| Packing size | 2140x1060x1750mm |