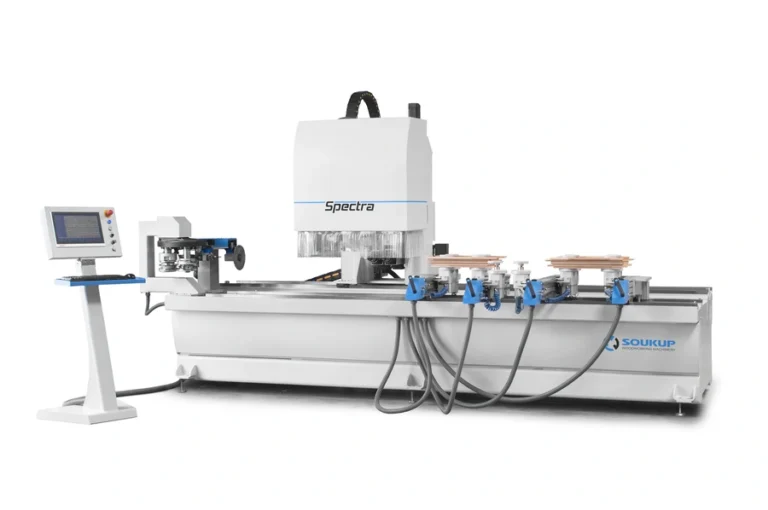

The Soukup Wizard 4L Machine machining centre comprises two independent machines, one for tenoning and one for profiling. The Soukup Wizard 4L Machine can be controlled as an integrated working centre or as two independent machines via an industrial PC running specialised control software, with the operator interacting through a touch screen panel.

The capacity of the Soukup Wizard 4L Machine is approximately 30–40 single-leaf windows per shift using the traditional technique of outside milling of sashes. The machine can produce around 60 knock-down windows by using the left working spindle for milling from both sides.

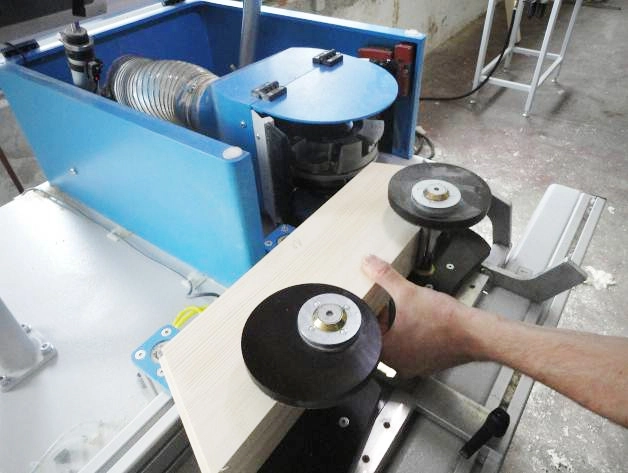

The Wizard 4L model, with its unique configuration, enables pre-squaring production. The tenoning operation is carried out by spindles long enough to accommodate all types of tenoning tools. SOUKUP’s unique tenoning cycle tenons and mills the outer shape of the timber end in a time-efficient manner. The dual configuration of the left and right profiling spindles ensures precision, which is essential for this system. As only a single machine operation is involved, the process is both fast and accurate. All units are driven by high-speed brushless motors, and the long gear feeder guarantees smooth surface finishes.