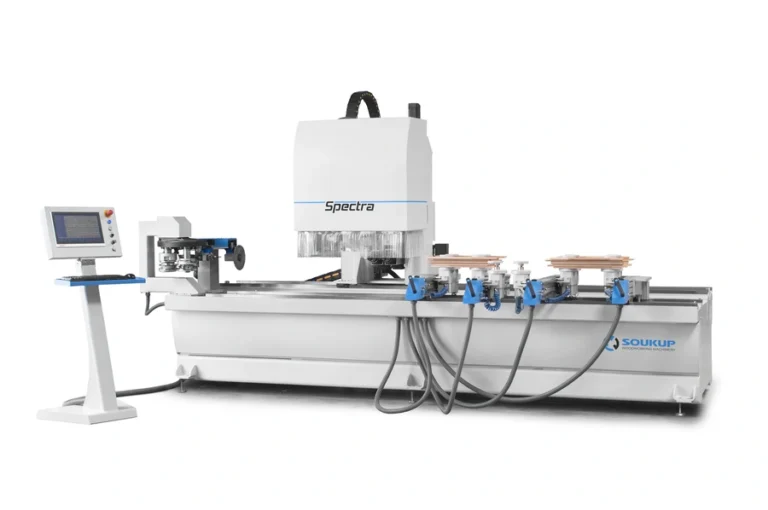

The Soukup Wizard Tenon CNC Window Machine incorporates thoroughbred industrial design based on the successful WIZARD machining centre. It features a generous spindle length of 620 mm with an upper supporting bearing and is designed for easy tool replacement. The machine can achieve multi-faceted processing of timber during a single pass. These are the main features of the Soukup Wizard Tenon CNC Window Machine.

The Soukup Wizard Tenon CNC Window Machine has been designed for tenoning of all types of timber frame construction, particularly for windows and doors. The base of the tenoning machine is constructed from heavy, rib-structured steel to provide a solid, compact machine that is rigid and highly resistant to heavy loads and stress.

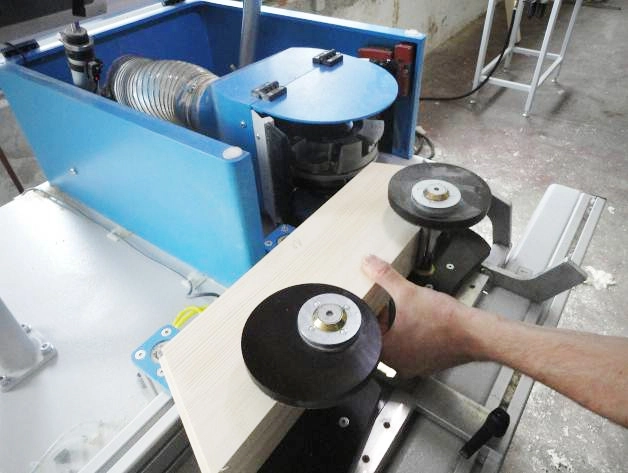

The tenoning unit moves on precision linear bearings driven by a precision ball screw. The cut-off saw and the tenoning fence have electronic adjustment. The tenoning carriage moves on linear bearings with variable speed controlled by an inverter drive. The tenoning fence can swivel up to 60° under programmable control. All units are connected to a central lubrication system. During operation, the operator places two pieces of timber on the tenoning table, selects a program, and sets the tenoning fence to the length specified in the work list.

Timbers are tenoned while moving forwards and backwards through the machine, making it possible to create multiple profiles in a single operation. The Soukup Wizard Tenon CNC Window Machine is controlled by a BECKHOFF industrial PC with a 12” touch screen running a Windows Embedded operating system. The control unit is mounted on a swivelling panel to ensure ease of use for the operator.