Soukup Crossline 650m Automatic Angle Cross Cut Saw with Trenching

Please contact us for pricing

The Soukup Crossline 650M is a high-performance CNC cross-cutting centre built for precision, speed, and efficiency in modern timber production. Designed for industrial-scale timber processors, it automates the cutting process with exceptional accuracy, helping to minimise labour costs and maximise productivity.

Soukup Crossline 650M – CNC Cross-Angle Cutting Centre

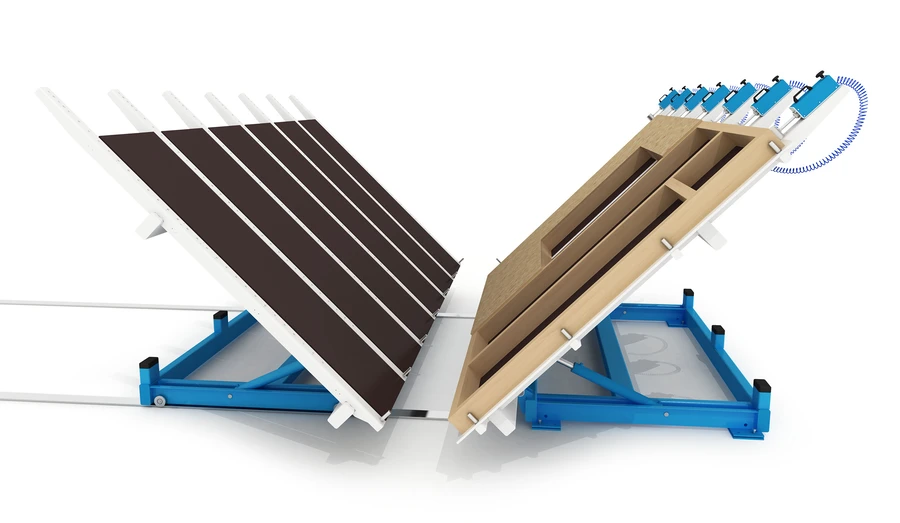

Timber Truss Production

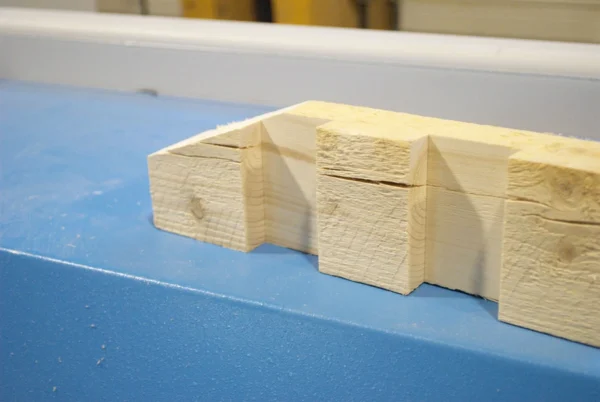

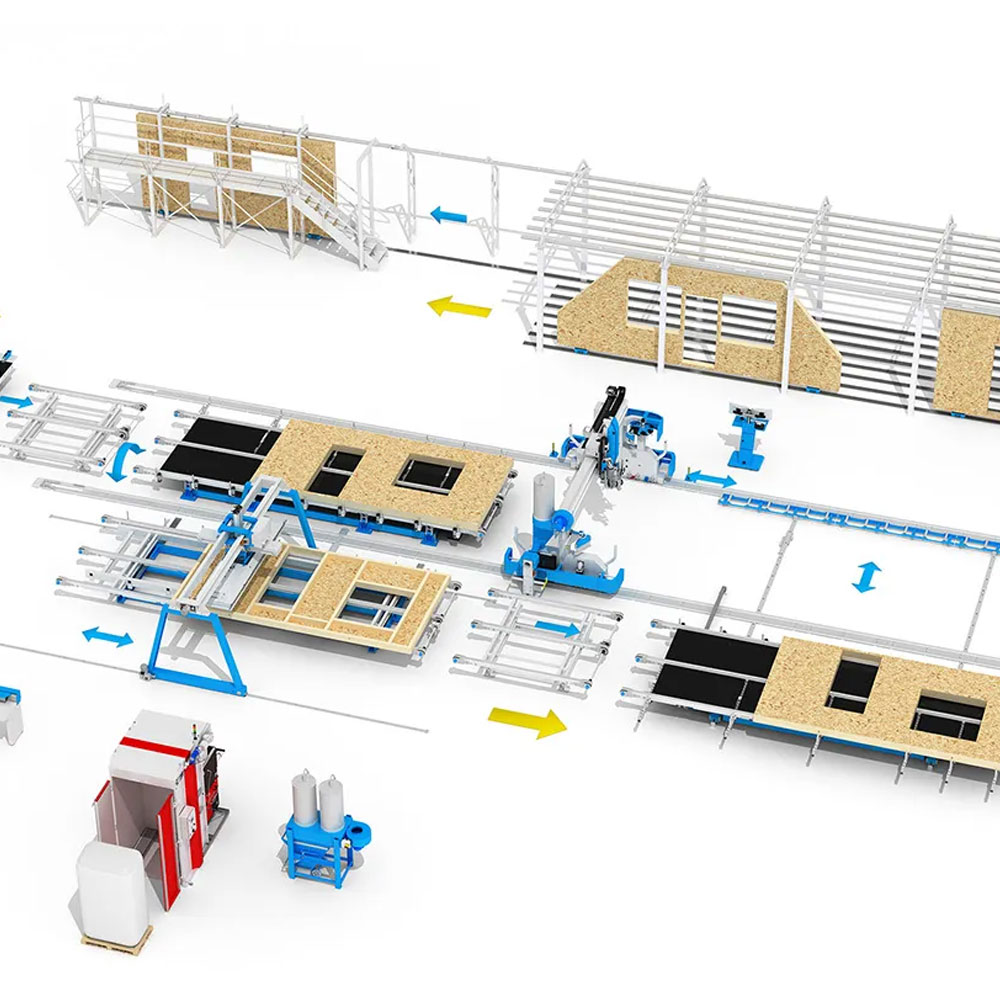

The Crossline 650M is perfectly suited to timber truss production, where speed, accuracy, and reliability are critical. By automating cross-cutting with CNC precision, it ensures every timber section is cut to the exact specification, minimising errors and reducing material waste. This makes it a valuable asset for truss manufacturers looking to improve throughput and consistency.

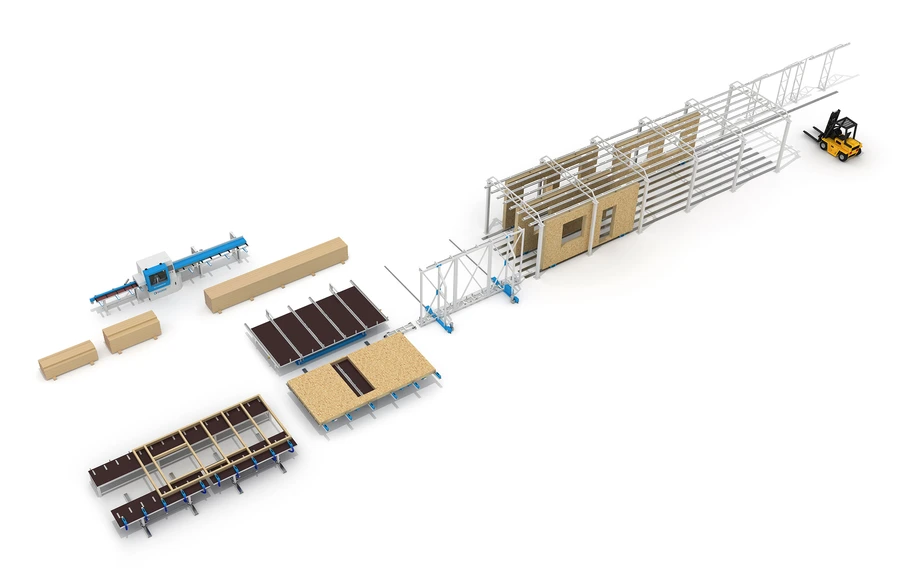

Offsite Timber Frame Applications

With the rise of offsite timber frame construction, the Crossline 650 provides the accuracy and speed required for pre-fabricated building components. It allows manufacturers to cut large timber elements quickly and consistently, supporting efficient offsite assembly and reducing build times on-site.

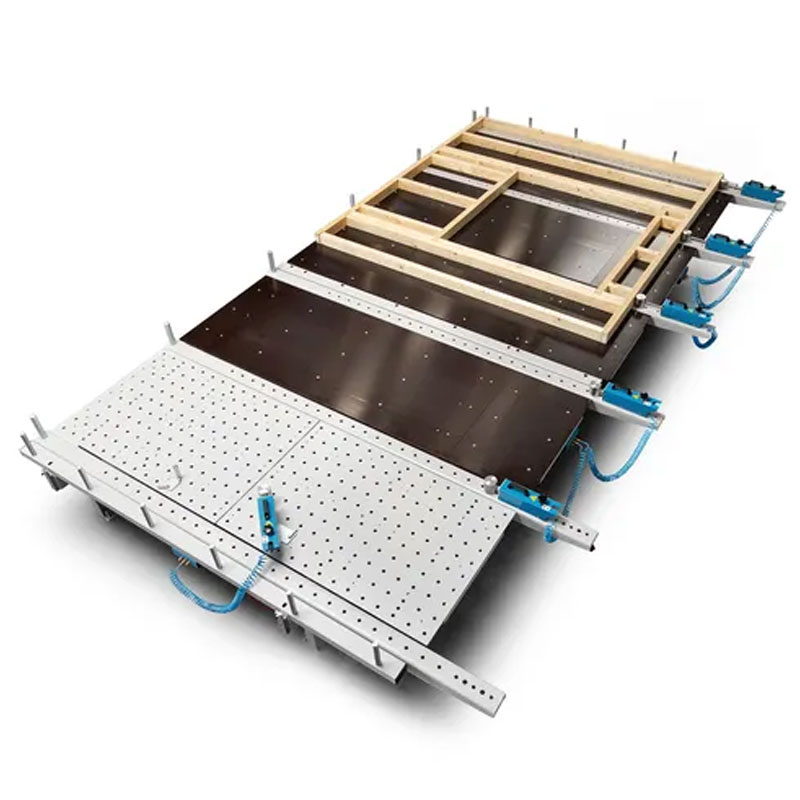

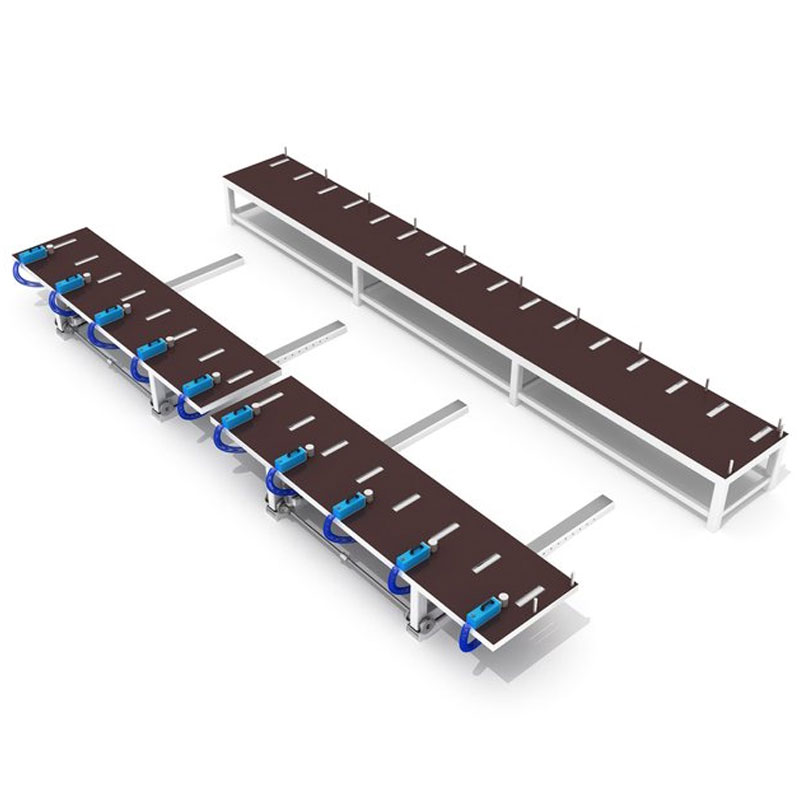

Easy To Integrate With Production Lines

Once the wood is in place, clamped, and the cutting angle is set, the blade rises automatically to cut the material. After the cutting job is complete, the article automatically moves from the cutting zone to the outfeed table.

The machine is versatile as it can be used in both manual or automatic mode. For automation, data can be controlled via WinCreator or your existing third party software (Must be BTL format). The Crossline 650G can seamlessly fit into your current operation. It can be integrated with production lines using conveyors and manipulators.

Crossline 650M

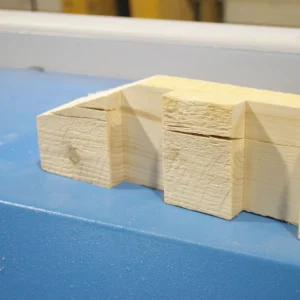

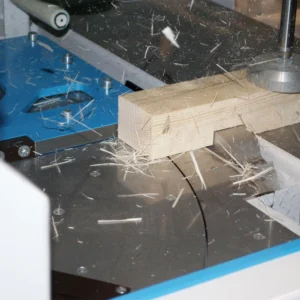

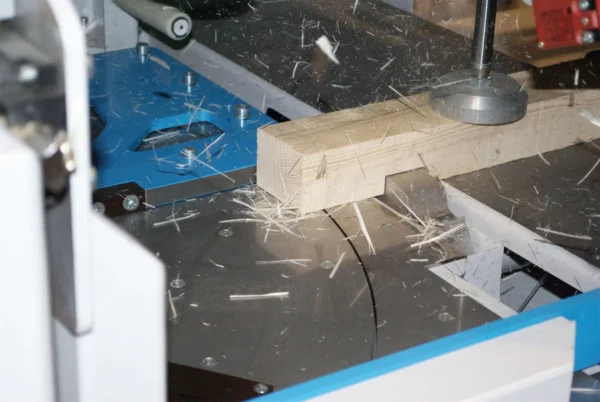

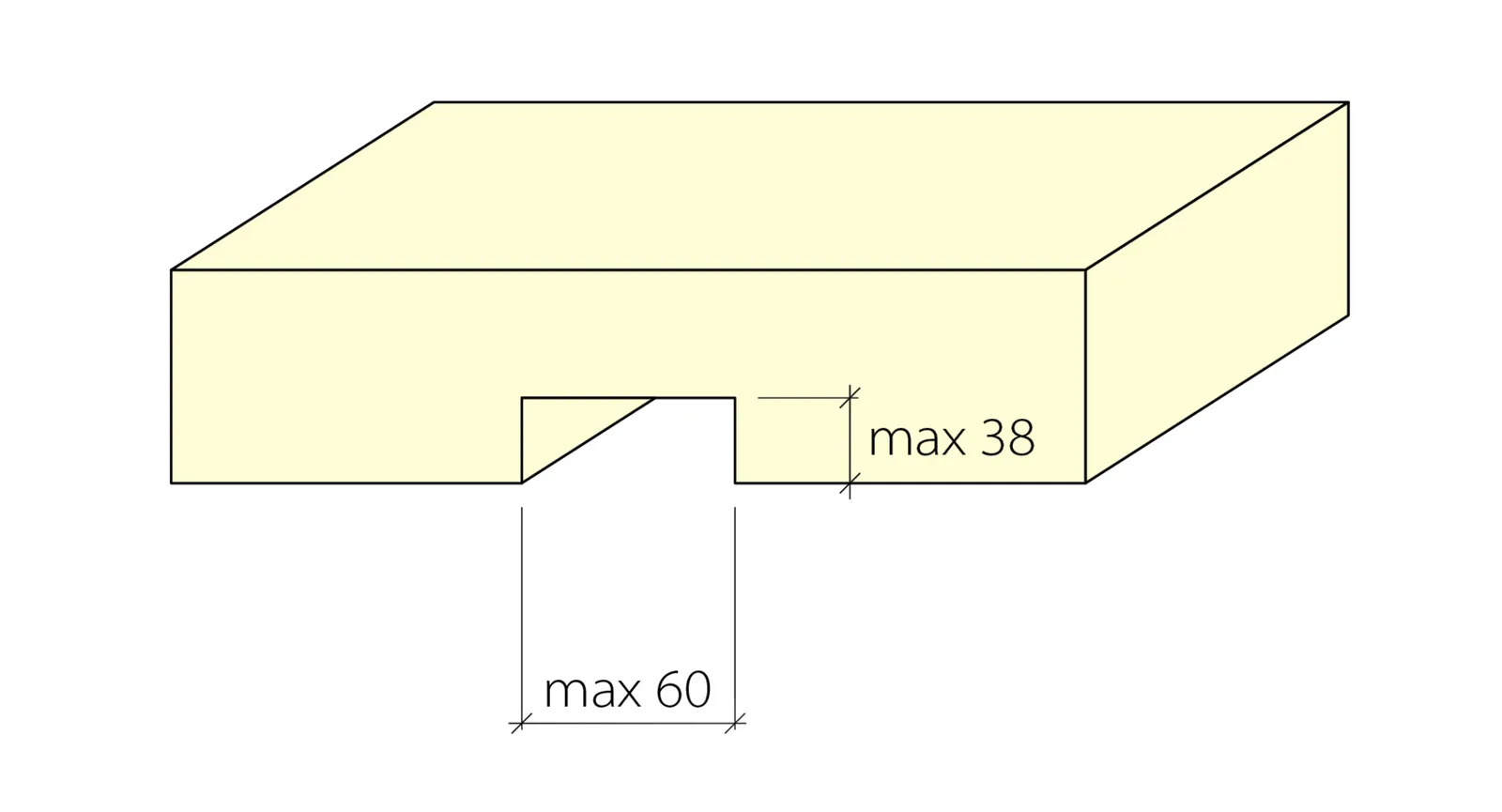

Crossline 650M is supplemented with a grooving module. Its use is where we need to combine the production of trusses with the cutting of material for wall panels for the exact position of the studs in the structure.

Crossline 650M, thanks to its functionality, is an efficient complex solution and often is an alternative to complicated machining centres in the prefabrication of wood-based panels.

Width of the groove max 60 mm (according to tools).

Send Enquiry

Please answer the questions below, tick the relevant boxes, and submit the form for a detailed machine quotation.

Description

Technical data Crossline 650M

- Beckhoff industrial PC with 12“ touch screen

- saw blade Ø 650 mm, 2800RPM saw blade motor 7.5 kW (10HP)

- turntable rotation 20°-160°

- saw blade lifting speed regulation

- upper and side pneumatic clamps with individual pressure regulation

- cut tolerance ±0.5 mm/bm

- feeding speed (0-60 m/min)

- automatic material measuring

- soundproof design dust extraction outlet ø120 mm + ø100 mm