Complete Wooden Panel Manufacturing

Please contact us for pricing

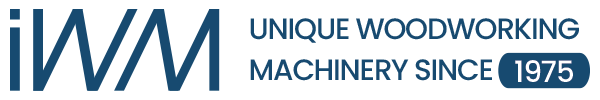

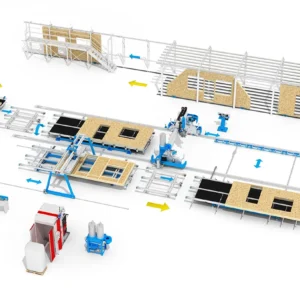

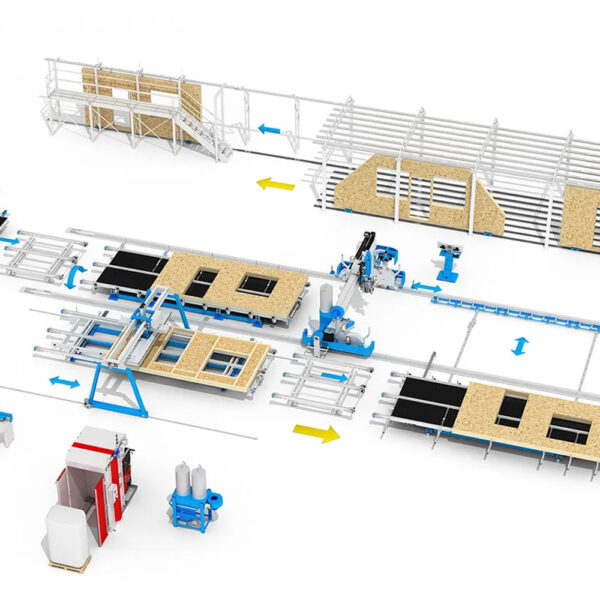

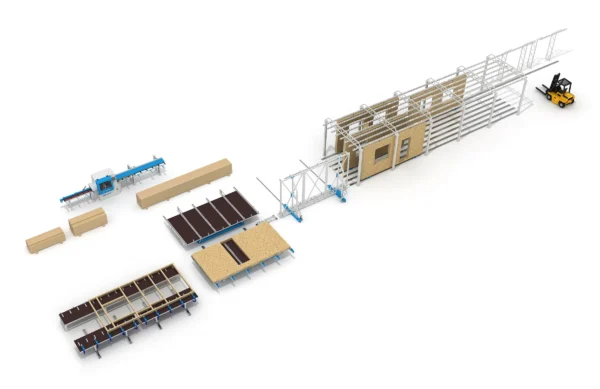

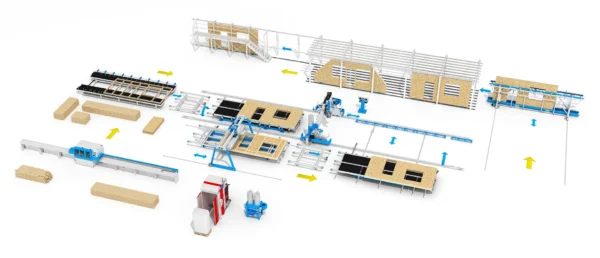

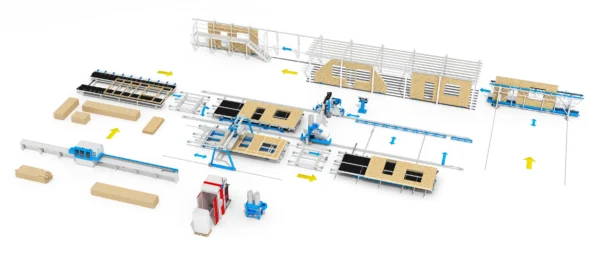

Prefabricated and modular construction is transforming modern timber building, and IWM’s complete wooden panel manufacturing solutions make it possible to produce high-quality, energy-efficient components with precision and consistency. Designed for seamless CAD/CAM integration, our machinery enables accurate processing, optimised material use, and tight, well-insulated joints every time. Built for reliability and speed, these systems allow manufacturers to streamline production, maintain uniform quality, and deliver exceptional results in both sustainable housing and large-scale timber construction projects.

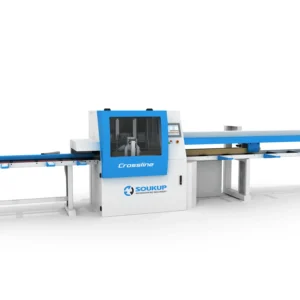

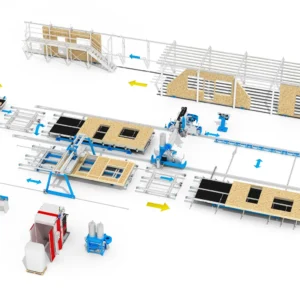

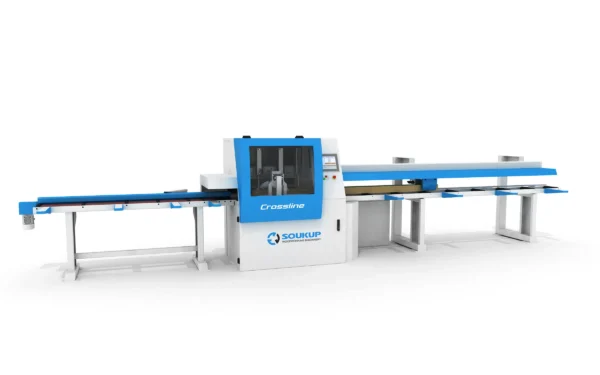

- CROSSLINE 500, 500M, 650, 650M—automatic crosscut saw equipped with a turntable and grooving module

- PONTEC – The multifunctional CNC-controlled bridge

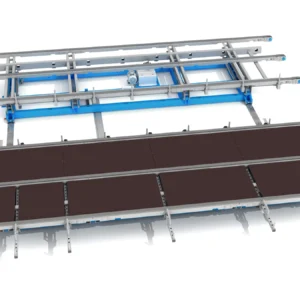

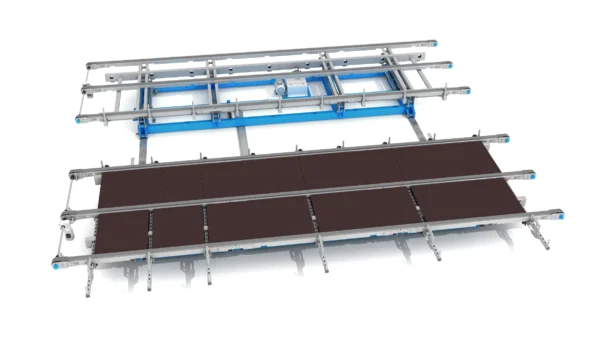

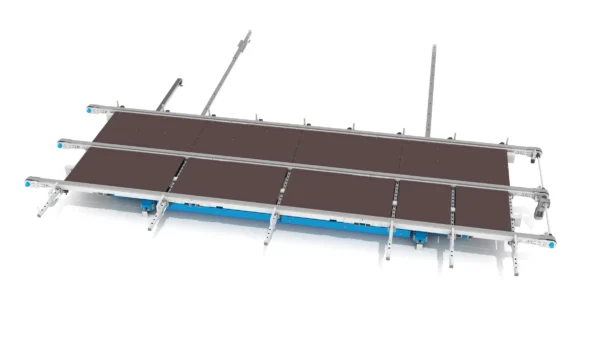

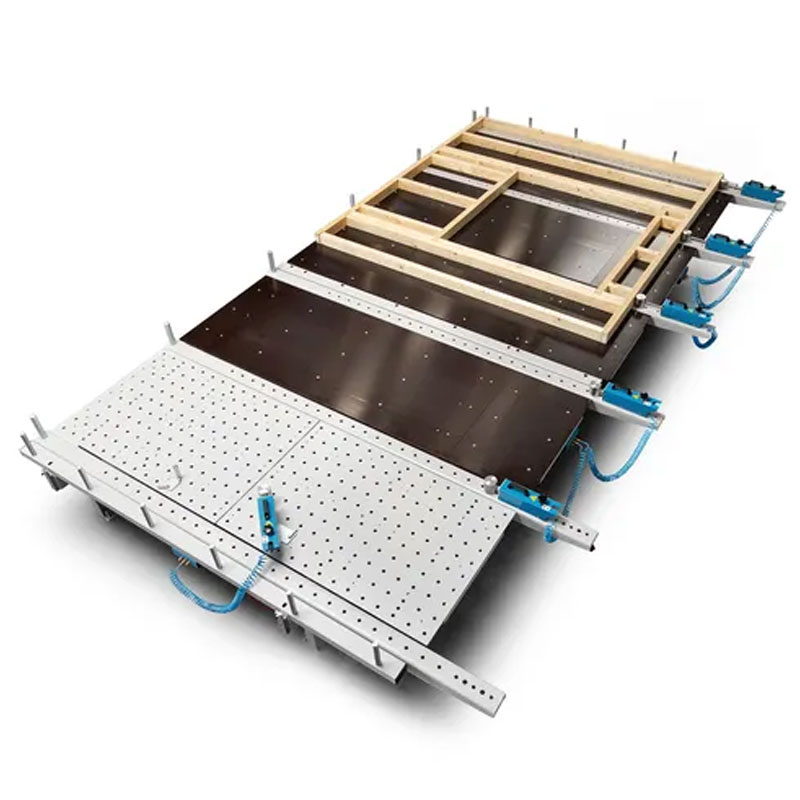

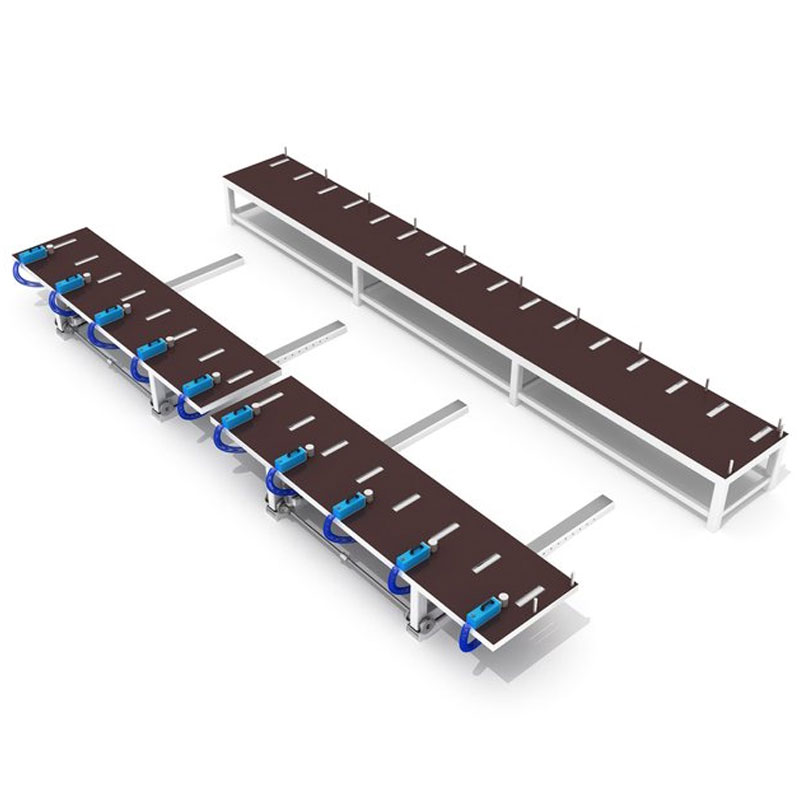

- FRAMER LINE – assembling table

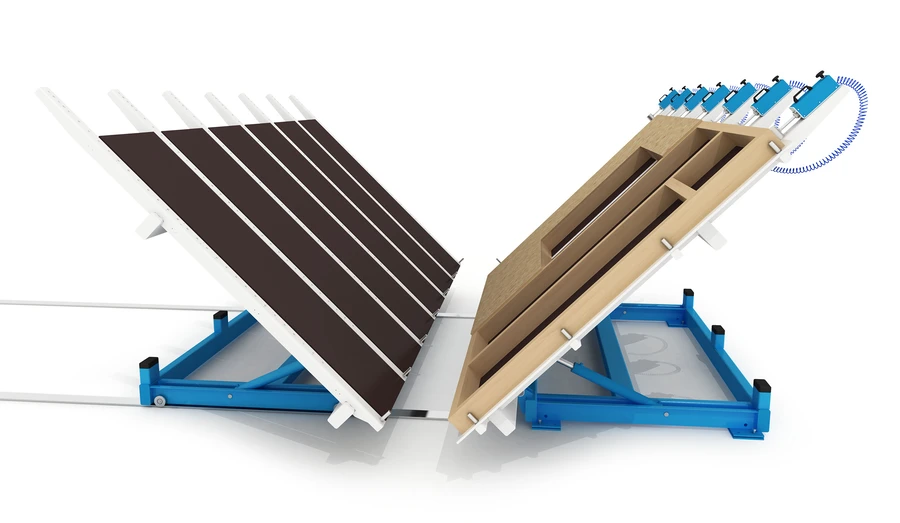

- WING – tilting assembling table (couple)

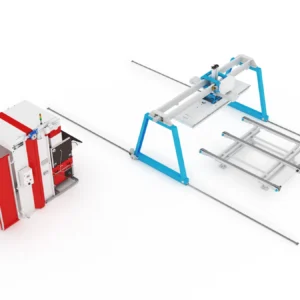

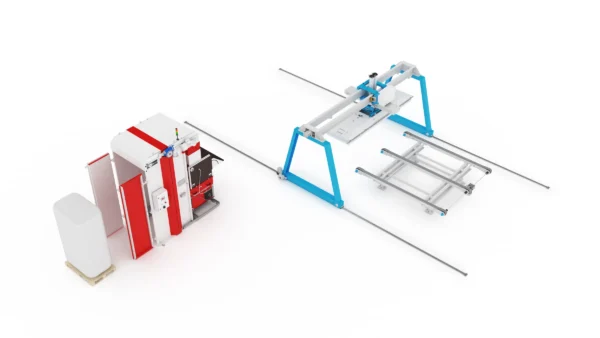

- X-FLOC – portal for blown insulation

- MOVER – tilting assembling table (single)

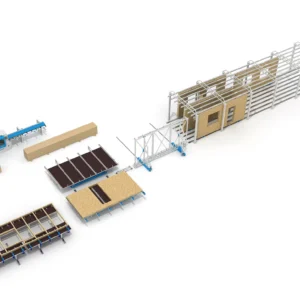

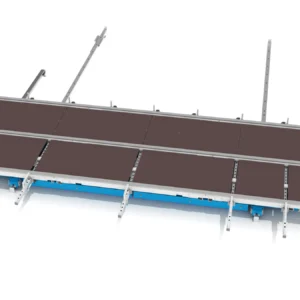

- TRANSPORTER – moves panels from the assembly tables into and out of storage

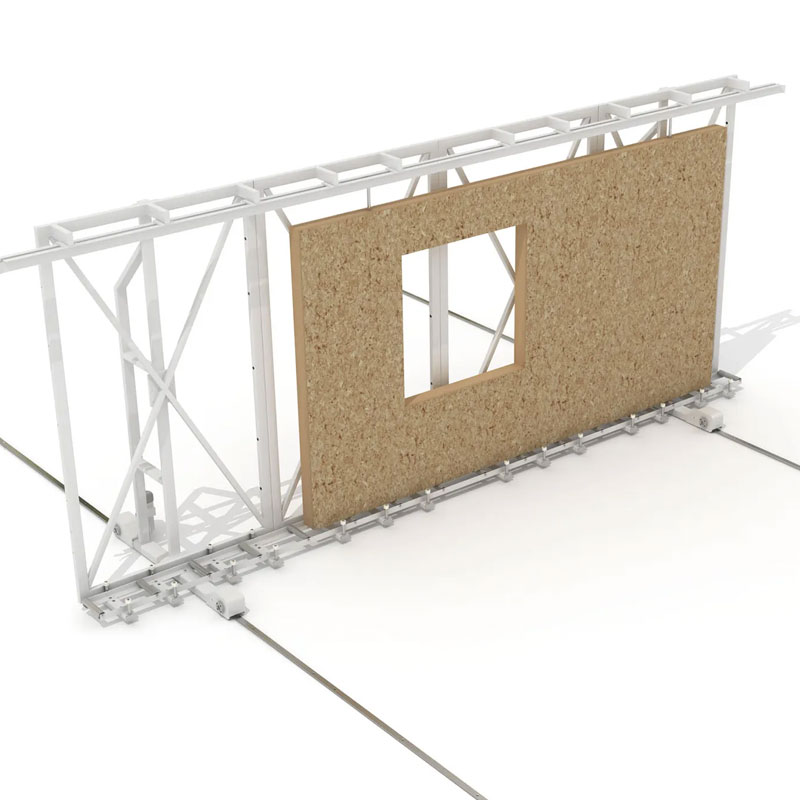

- STORAGE – holds the panel upright for finishing and for storage awaiting dispatch

Send Enquiry

Please answer the questions below, tick the relevant boxes, and submit the form for a detailed machine quotation.

Description

Benefits of our Wooden Panel Manufacturing technology

- Lower worker overhead

- Fast and safe handling of panels

- Small production area requirement

- Production hall with low ceiling height – reduced heating and maintenance costs

- Optimized technical solution with uniform capacity across all workstations

- Possibility of gradually increasing capacity

- Economically balanced investment