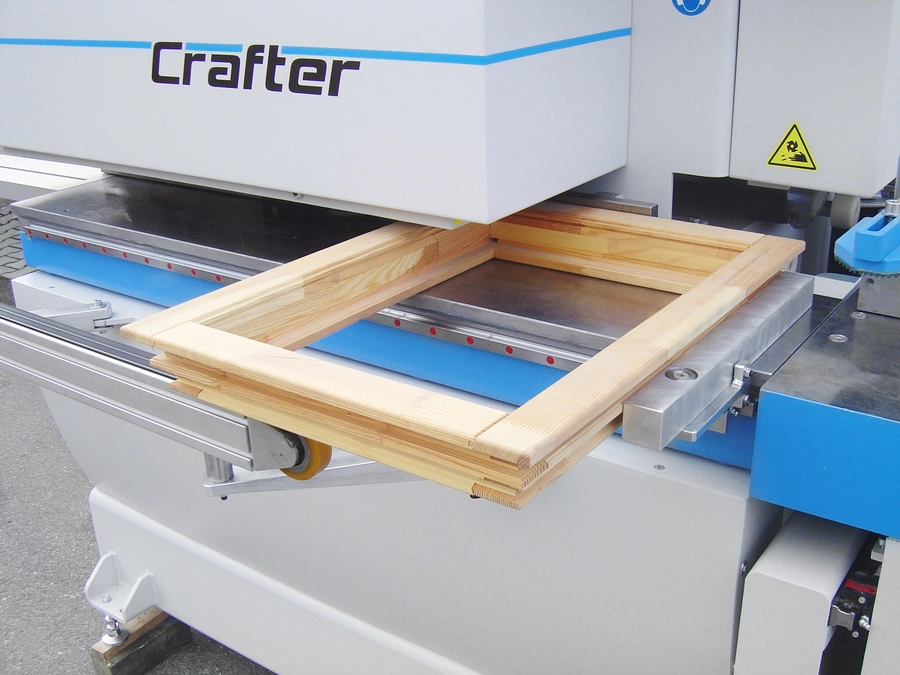

Double End Curved Profile Sander

Integration of Touch Screen

The touch screen interface allows for easy setting of working width, jumping function parameters on the first moulding system, feed speed, and RPM of various working units.

Sizing System (S)

The top and bottom saw construction is designed to prevent tearing issues when cutting laminated panels. The closely positioned scoring and main saw blades facilitate easy adjustments.

Profile Sanding System (PS)

The oscillating sanding mechanism ensures an extremely fine surface finish and can swivel to angles of up to ±15º.

Feed Chaintrack

The feed chaintrack is equipped with needle bearings to increase wear resistance and comes with a choice of rubber or phenolic surfaces.

First Moulding System (PM1)

The first moulding system can swivel to angles of up to ±90° and includes an optional cutter jumping function. It is powered by high-frequency motors.

Brush System (BS)

The brush system can tilt to angles of up to ±90° and can be equipped with polishing wheels made of various materials, such as non-woven grinding wheels and forming wheels. It also features an auto-compensation fitting.

Precision Linear Guideways

The movable side of the Double End Tenoner (DET) is mounted on precision linear guideways to ensure accuracy.

Second Moulding System (PM2)

The second moulding system can also swivel to angles of up to ±90° and is powered by high-frequency motors.

Working Configuration

The machine’s configuration can be customized to meet specific requirements, ensuring optimal performance and precision.

-

SPECIFICATION ECT-DS68 ECT-DS88 ECT-DS108 Working units

(refer to brackets below)PS+PS+BS PM2+PS+PS+BS S+PM1+PM2+PS+BS Max. working width 2600mm 2600mm 2600mm Min. working width 250mm 250mm 250mm Max. working thickness 80mm 80mm 80mm Feed Chaintrack Motor horse power 3hp 5hp 5hp Feed speed 5-25m/min 5-25m/min 5-25m/min Distance between dogs 400(300/200)mm 400(300/200)mm 400(300/200)mm Movable Side Shifting System Motor horse power 1hp 1hp 1hp Feed speed 2m/min 2m/min 2m/min Scoring Saw System (S) Motor horse power – – 2(3/5)hp Spindle speed – – 3450rpm(60Hz) Spindle diameter – – 25.4(30)mm Sawblade diameter – – 205mm Main Saw System (S) Motor horse power – – 5(7.5)hp Spindle speed – – 3450rpm(60Hz) Spindle diameter – – 25.4(30)mm Sawblade diameter – – 255mm 1st Moulding System (PM1; equipped with jumping function) Motor horse power – – 5(7.5/10)hp Spindle speed – – 3000/8000rpm Spindle diameter – – 40mm Cutter diameter – – 180-210mm 2nd Moulding System (PM2) Motor horse power – 5(7.5/10)hp 5(7.5/10)hp Spindle speed – 3000/8000rpm 3000/8000rpm Spindle diameter – 40mm 40mm Cutter diameter – 180-210mm 180-210mm Profile Sanding System (PS) Motor horse power 3hp 3hp 3hp Sanding belt width 30-80mm 30-80mm 30-80mm Sanding belt length 2070mm 2070mm 2070mm Speed 0-1800rpm 0-1800rpm 0-1800rpm Brush System (BS) Motor horse power 2(3)hp 2(3)hp 2(3)hp Speed 0-1800rpm 0-1800rpm 0-1800rpm Weight N.W. 4500kg 5350kg 5600kg G.W. 5200kg 6200kg 6500kg Dimensions Machine size (mm) 4700x3960x1470mm 4700x4490x1470mm 4700x5100x1470mm Packing size (mm) 4900x2280x1750mm 40ft container 40ft container

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Why IWM

Why choose IW Machines?

IWM have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands