Falach 100

Falach 100 Briquette Machine

Price: P.O.A

IWM Falach 100 Briquette Machines have established themselves as the UK’s Leading Choice of Hydraulic Briquette Machines converting wood waste and other materials into renewable energy briquettes which have been Certified to meet the “Clean Air Strategy” producing same heat as Coal and no Air Pollutants.

Features

- 90-120 Kilos Per Hour Production

- 70mm Dia Briquettes

- Dimensions L x W x H 222 – 120 – 151cm

- Weight of Press: 810kgs

- Hopper Volume: 0.75 m3

- Pump motor input: 11 KW

- Power consumption: 8.2 KW/hour

- Oil cooler: Yes

- Operation: Continuous

- Auto Reverse Vertical Agitator: Yes

- Automatic Switch-out: Yes

- Make noise level: 68dB

- This machine is 3 phase 32 amp

IWM Falach Briquette Machines have established themselves as the UK’s Leading Choice of Briquette Machines , “Tested & Certified” to meet the Governments “Clean Air Strategy” converting your wood waste into renewable energy high energy briquettes producing same caloric heat as coal without any air pollutants.

IWM 5 Bag Carousel Units All our machines can be fitted with an optional Five Bag Carousel unit that will collect all your briquettes and separate them into different bags. 5 Bag Carousel Unit for Falach 100 £1480

Our Falach Briquette machines have many unique design features that are approved by customers.

- Funnel-shaped Hopper

- Chromed Piston and Press Chamber

- Electrical Interlocked Lid

- Hydraulic Cooler

IWM Falach Briquette Machines have a unique funnel-shaped hopper that allows the wood waste material to fully load into the hydraulic Chromed Piston to manufacture solid briquettes. Falach Briquette Machines are fitted with a Vertical Agitator to ensure that any waste materials are fully loaded into the pressing chamber to produce sturdy briquettes. As opposed to the horizontal agitators that are found in other woodworking machines that do not fully load the pressing chamber and produce softer briquettes.

Falach Briquette Machines are fitted with a Hardened Chromed Piston and Press Chamber. The Result of Chromed Piston itself is hard-wearing compared to a steel piston, and a chamber that are prone to wear.

The electrical interlocked lid allows to fill the machine hopper manually and provides a total safe working environment for operators with the added advantage preventing clouds of dust when filling the hopper from extraction bags into the atmosphere.

A hydraulic cooler and fan are fitted to the Falach 100 to ensure that the hydraulic oil is at optimum pressure. Potentiometre Falach 100 Models are fitted with a adjustable Potentiometer providing greater control of the optimum length of the briquettes depending on the density of materiel being pressed.

The Automatic 5 Bag Carousel Unit collects the briquettes into 5 Bags each holding 20/25 Kilos and offers a perfect storage solution as the briquettes can be placed into easy to handle bags that can be sealed to keep damp air away. These bags can also be easily stored on top of one another for convenience.

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Falach 100

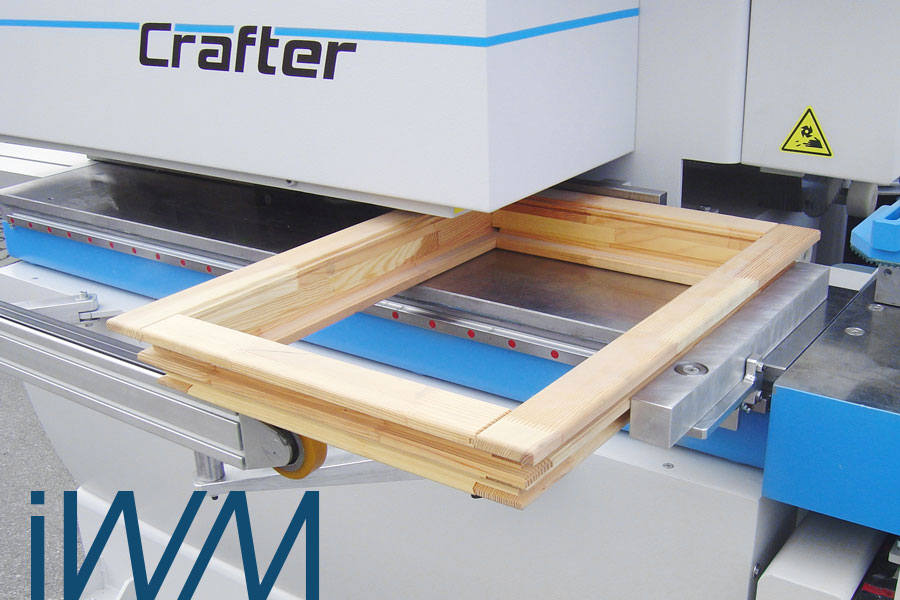

Machine Gallery

Why IWM

Why choose IW Machines?

IWM have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands