Wizard Tenon

Soukup Wizard Tenon CNC Window Machine

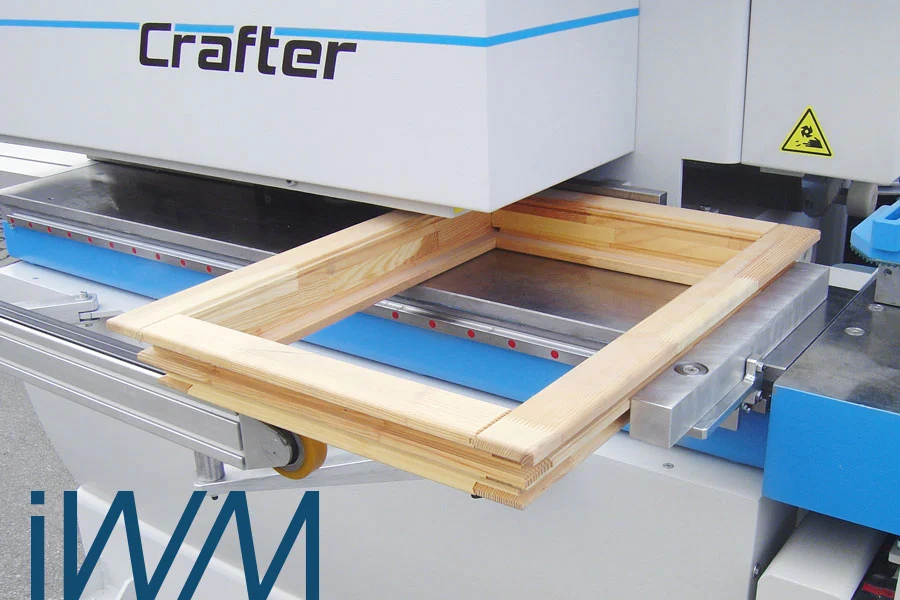

The WIZARD TENON incorporates thoroughbred industrial design based on the successful WIZARD machining centre. It has a generous spindle length of 620 mm with an upper supporting bearing and is designed for easy tool replacement. It can achieve multi-faceted processing of the timber during a single pass through the machine. These are the main features of the machine.

The WIZARD TENON CNC tenoning machine has been designed for tenoning of any timber frame construction but especially windows and doors. The base of the tenoning machine is constructed from heavy rib structured steel to obtain a solid compact machine which is rigid and highly resistant to heavy loads and stress. The tenoning unit moves on precision linear bearings driven by a precision ball screw. The cut-off saw and the tenoning fence have electronic adjustment. The tenoning carriage moves on linear bearings with variable speed controlled by an inverter drive. The tenoning fence can swivel up to 60° under programmable control. All units are connected to a central lubricating system. In operation the operator puts two pieces of timber on the tenoning table. He selects a program and sets up the tenoning fence to the length specified in the work list. Timbers are tenoned when going forwards and going backwards through the machine thus it is possible to make multiple profiles in one go. WIZARD TENON is controlled by a BECKOHOFF industrial PC with a 12“ touch screen running a Windows Embedded operating system. The control unit is mounted on a swivelling panel to provide ease of use to the operator.

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Wizard Tenon CNC

Machine Gallery

Why IWM

Why choose IW Machines?

IWM have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands