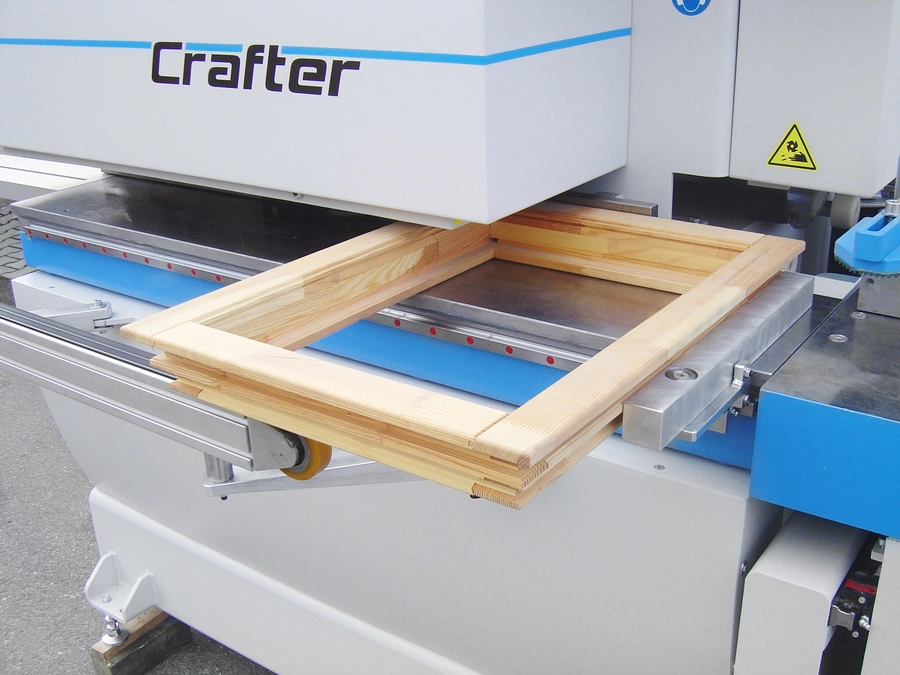

Crafter

Soukup Crafter CNC Machining Centre

The UK SERIES Soukup CNC Window Centre Model CRAFTER has become the leading choice of Many UK Joinery Companies who wanted to increase productivity by 40% and manufacture efficiently at least 10/15 Box Sliding Sash 15/20 Casement Windows & Doors each Day with just One Operator . It is the only machine on the market to optimise productivity for Box Sliding Sashes, Casements & Doors with our standard Soukup Wincreator Software . Find out how you can also increase your productivity and profits by simply completing the Tick Box Survey to receive a 3 in 1 Total Package Price for a Soukup Crafter complete with Software & Tooling , Delivered, Installed & including Operator Training in your Workshop

- tenoning and profiling of box parts intended for balance springs

- notching of cill part for interior lining bead

- profiling of divided cill in part

- trenching of slot in cill and head for pulley stiles

- cutting operation for moulded pulley stiles, lining beads, cill extension

NB. Pulley stiles, lining beads, head and cill extension are moulded off-line

- milling of horns in different moulds

- open tenons and slots

- profiling of traditional bevelled meeting rails

- adapting of meeting rail slots to parting bead

- outside profiling and grooving for cord, gasket or balance springs

NB. Mortising of sash stiles is made off-line

- tenoning and profiling of frames

- tenoning and profiling of casements with shorted rails tenon for stormproofing

- recovering of glazing beads and sticking bars from frame rebate

- tenoning and profiling of casements with full machining of components without stormproofing (flush, stormproof & high performance windows)

Antisplitting spindle jumping on the corner has been minimised with the original Soukup machine. During the double cycling of tenoning, the CRAFTER makes sure that any cross wood parts have been suitably milled out. As a result, this woodworking system means that milling of small sashes is easier than ever, where stability had once been an issue.

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Crafter

Machine Gallery

Crafter

Machine Videos

Why IWM

Why choose IW Machines?

IWM have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands