Crossline 650

Soukup Crossline 650 Automatic Cross Cut Saw

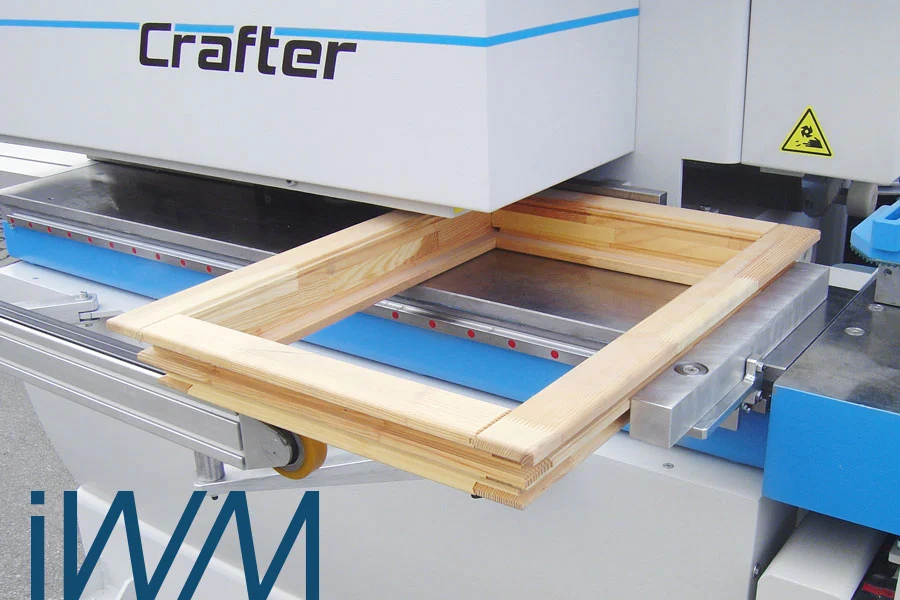

The Crossline 650 is an automatic crosscut saw machine featuring a 650mm diameter blade. The mounted saw turntable allows for angled cuts of up 70 degrees. A servo-driven loader automatically feeds this high-quality saw for quick and efficient operation.

Scanners within the cutting area of the saw, detect the wood as it is fed into the machine. When the material is detected, the blade automatically raises to complete the required cut. For superior cutting accuracy, the Crossline 650 includes pneumatic clamps. Two side and two upper pneumatic clamps hold the piece securely in place during the cutting process.

Operated by Wincreator

As the materials are placed within the machine, clamps are automatically deployed for securing during machine operation. Once the angle is set, the blade rises to carry out the required cut. After completion of the process, the material is automatically released and pushed from the cutting zone. Contents are seamlessly moved to the outfeed table once the manufacturing process is finished. The Crossline 650 can be operated in manual mode or automated with data from WinCreator or compatible third-party software. Optional elements include label printers for quick and easy identification of finished pieces.

- 650mm diameter saw blade

- 75kW motor

- Cutting angle up to 70 degrees

- Pneumatic clamps – dual upper and side

- Automatic measuring of material

- 10-inch touchscreen

- Automatic workflow for cutting batches

- soundproof design dust extraction outlet ø120 mm + ø100 mm

- Cut Angle – 20° – 160°

- Feed Speed – 0 – 60 m/min

- Saw blade motor – 7,5 kW (10 HP)

- Tolerance – 0,5 mm/m

- Dust extraction – 120 + 120 mm

- Touch screen control – 12˝

- Size – 13350mm (L), 1270mm (W), 1805mm (H)

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Crossline 650 Automatic Cross Cut saw

Machine Gallery

Crossline 650 Automatic Cross Cut Saw Machine

Machine Videos

Why IWM

Why choose IW Machines?

IW Machine have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands