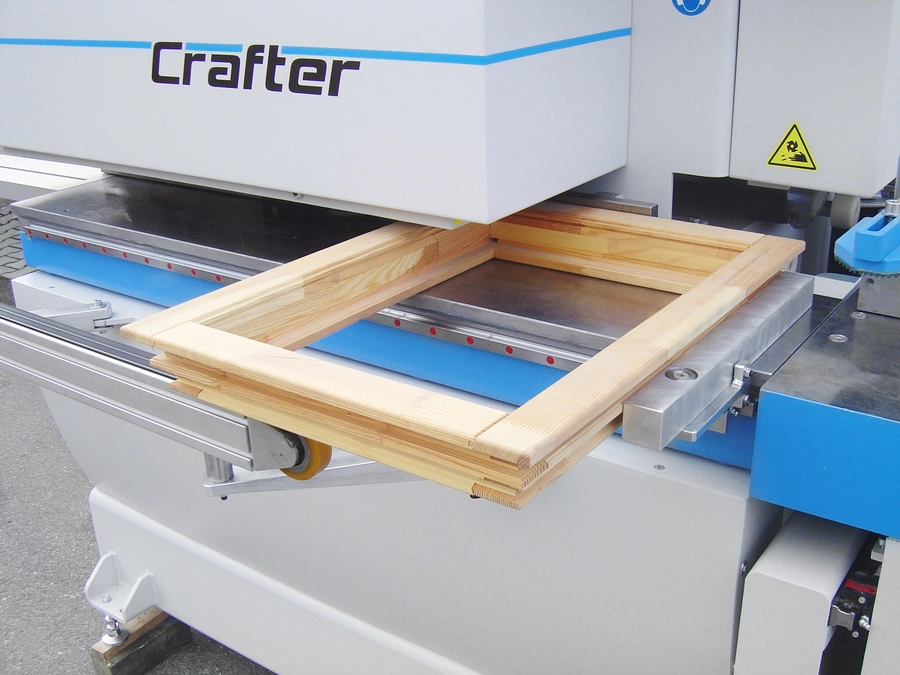

Edgebander

Flexa 37 - Edge Banding Machine

The edge banding machine Flexa 37 EM-5, RMA-6 & RMAT-7 are the perfect solution for the medium commercial or residential manufacturer for efficiently processing PVC, tape, laminate or wood strips. Standard with 2-motor end trim, top and bottom trim, scrape and buff the Flexa 37 also is available with pre-mill and diamond corner rounding unit.

The Flexa 37 series is equipped with a myriad of advanced features to streamline your edge banding operations:

1. Dual Motor End Trim Experience unparalleled efficiency with the 2-motor end trim feature, guaranteeing precise trimming of excess edge banding material for a flawless finish.

2. Top and Bottom Trim Achieve impeccable results effortlessly with top and bottom trim capabilities, ensuring uniformity and consistency across all edges.

3. Scraping and Buffing Say goodbye to imperfections with integrated scraping and buffing functionalities, leaving your edge-banded surfaces smooth and polished to perfection.

Optional Enhancements for Customised Solutions

Tailor your edge banding experience to your specific requirements with optional enhancements available for the Flexa 37 series:

1. Pre-Mill Unit Opt for the pre-mill unit to further refine the edges of your materials, ensuring optimal bonding and seamless integration.

2. Diamond Corner Rounding Enhance the aesthetic appeal of your products with the diamond corner rounding unit, adding a touch of sophistication to your edge-banded surfaces.

Unrivaled Performance and Reliability

With the Flexa 37 series, you can trust in unmatched performance and reliability, empowering you to meet deadlines and exceed expectations with ease. Whether you’re producing furniture, cabinetry, or custom fixtures, these machines are engineered to deliver exceptional results consistently, allowing you to elevate the quality of your end products while maximising efficiency and profitability.

- Mega 300 TS Programmable Controller

- Teflon coated glut pot with automatic temperature reduction

- Quick remove glue tank;

- .4- 6 mm capacity

- 11 m/ min (36 f/min) feed speed

- 8mm-60mm (.3 – 2.4”) panel capacity

- High frequency motors

- Pneumatic positioning of units

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Why IWM

Why choose IW Machines?

IWM have been for the last 48 Years Supplying “Unique Quality New and Used” Woodworking Machinery Solutions to many workshops and business throughout the United Kingdom by Responding to your exacting requirements. Using All Our Invaluable Experience with “Honesty, Integrity & Total Respect”.

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands