Mütek Wood Shredding & Chipping Machine

The Mütek waste shredder boast sa formidable design that enables continuous operation, effortlessly shredding a multitude of materials. Whether it’s hard or soft woods, chipboards, OSB and plywood panels, construction timbers, paper, or cardboards, shredders are designed to handle them all.

Designed to shred many types of waste material, including building timbers, paper, and cardboards in addition to soft and hard woods, chipboards, OSB, and plywood panels. The strong steel design enables operations to be carried out continuously. The knives are able to spin several times before they need to be changed, have a low rate of wear, and are available in a variety of designs that are suitable for cutting all types of material.

Mütek shredders are designed to shred all kinds of waste material, including hard and soft woods, chipboards, OSB and plywood panels, as well as construction timbers, paper and cardboards. The sturdy steel construction allow for continuous operation. The knives are available in various designs for all kinds of material and feature a low wear and can rotate several times before they have to be replaced.

As standard mütek grinders include:

- Fast hydraulic

- Profile rotor

- Second row of knives

- Control cabinet with Siemens PLC

- Automatic Star/Delta Switch

- Automatic stop when the hopper is empty

- Removable exhausting channel

- 70 – 100 Rotor turnings for higher throughput

- Cycle control in order to prevent idling

- Performance-enhancing pacing of hydraulic sliders

Talk to iWM about this machine

Whether you’re ready to fill out an enquiry form or would like to ask a few questions, fill out this enquiry form and we will get back to you.

Mütek shredder

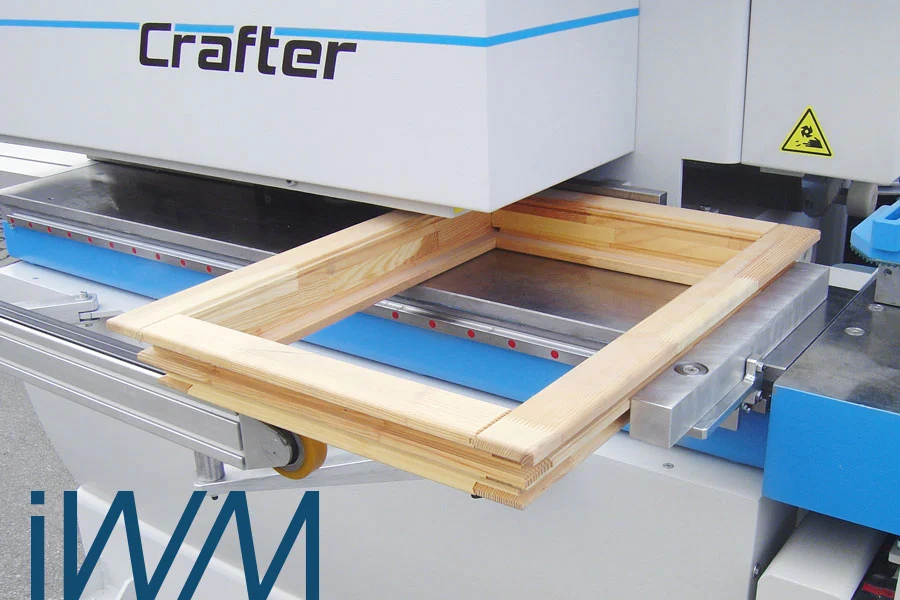

Machine Gallery

Why IWM

Why choose IW Machines?

- Over 48 years of experience

- Free professional advice

- Cost-effective solutions

- Market leading brands