IW Machinery

Briquette Machines

What is a Briquette Press Machine?

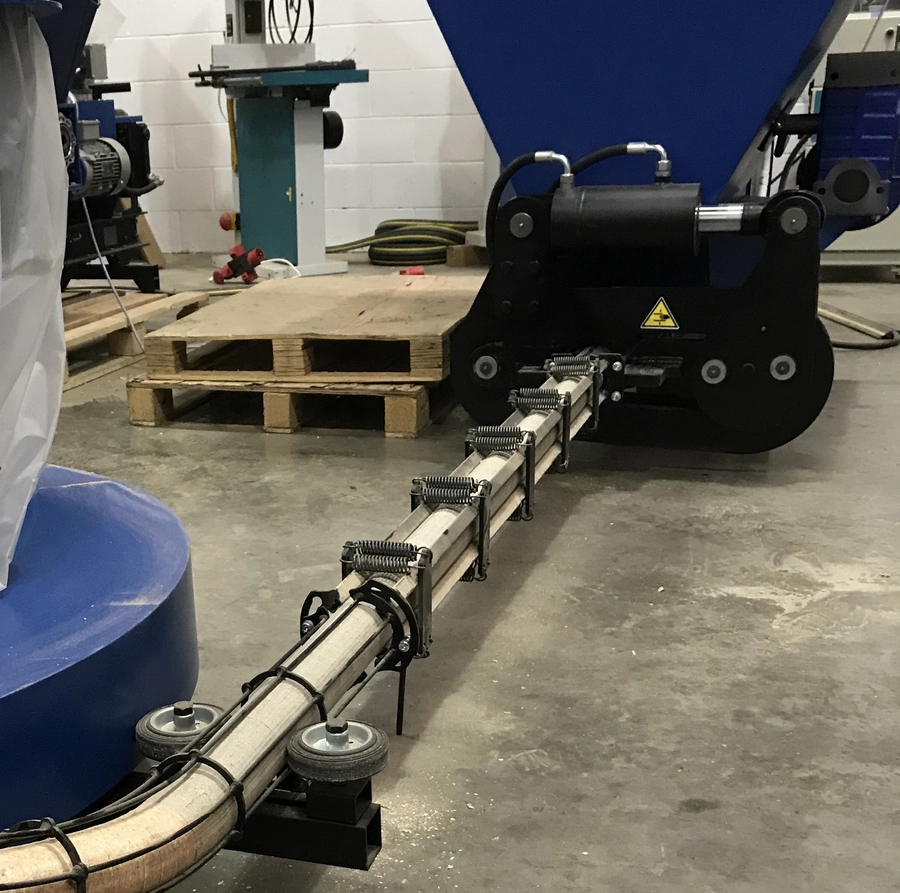

A briquette machine compresses a raw material such as wood shavings into a small log shaped fuel source of different sizes and dimensions (depending on the make and size of the machine).The material which is 15% moisture is compressed under high hydraulic pressure, without the use of any additives or glue. A naturally made product.

What is a Wooden Briquette

Commonly known as a Biomas Fuel (Briquette). Lignin found in the wood shavings binds the particles of wood together to form a solid log type structure, and can therefore replace the need for logs for firewood. A wood briquette burns more efficiently than firewood as the moisture content of a briquette can be as low as 5% whereas firewood can be20%+ moisture.

Make an environmental impact

Briquette machines in the UK are becoming more important since the Clean Air Strategy announcement from the government. A briquette machine can transform your wood shavings, chips and dust into carbon-neutral briquettes all in one place to prevent landfill. Not only are Falach Briquette Machines environmentally-friendly, but they are also one of the best-sellers in the joinery machinery industry where over 350 have been installed throughout the UK!

Existing Customers

If you would like to find out how these briquette machines can benefit your business, we can put you in touch with existing customers who can explain how our briquette machines have helped their business grow.

Increase your yearly income

Falach Briquette Machines are an excellent choice for productivity. The Falach 50 can produce up to 50kgs of briquettes per hour. Over the course of one week, 150 x 10kgs sacks of briquettes can be made and may sell for anywhere between £2.50-£3.00 per sack – a possible yearly income of over £12500!* (*based on 35-40 weeks of production). These machines will also heat your workshop during the colder months that can help to keep energy costs down.

IW Machinery

Enquire Now

Here to help

If you have any questions or enquiries, please get in touch.